ROBOTIC BIN PICKING SOLUTIONS

Unlock productivity with vision‑guided automation.

TrueLight deploys 3D vision‑guided robotics to reliably pick parts from random, semi‑structured, or structured bins, then place them to their next process step — safely, consistently, and at production speed.

What Is Robotic Bin Picking?

Bin picking is the process of locating, selecting, and extracting parts from bins where items can be fully random, semi‑structured, or structured, then handing them off to downstream processes. The degree of automation difficulty rises with part disorder and variability — packaging improvements can help, but are not always practical.

Production Flexibility

Customizable for varied parts and bins

Quick recipe changeovers

Scalable from single to multi-robot cells

Smart workflows for consistent throughput

Suggested Configurations

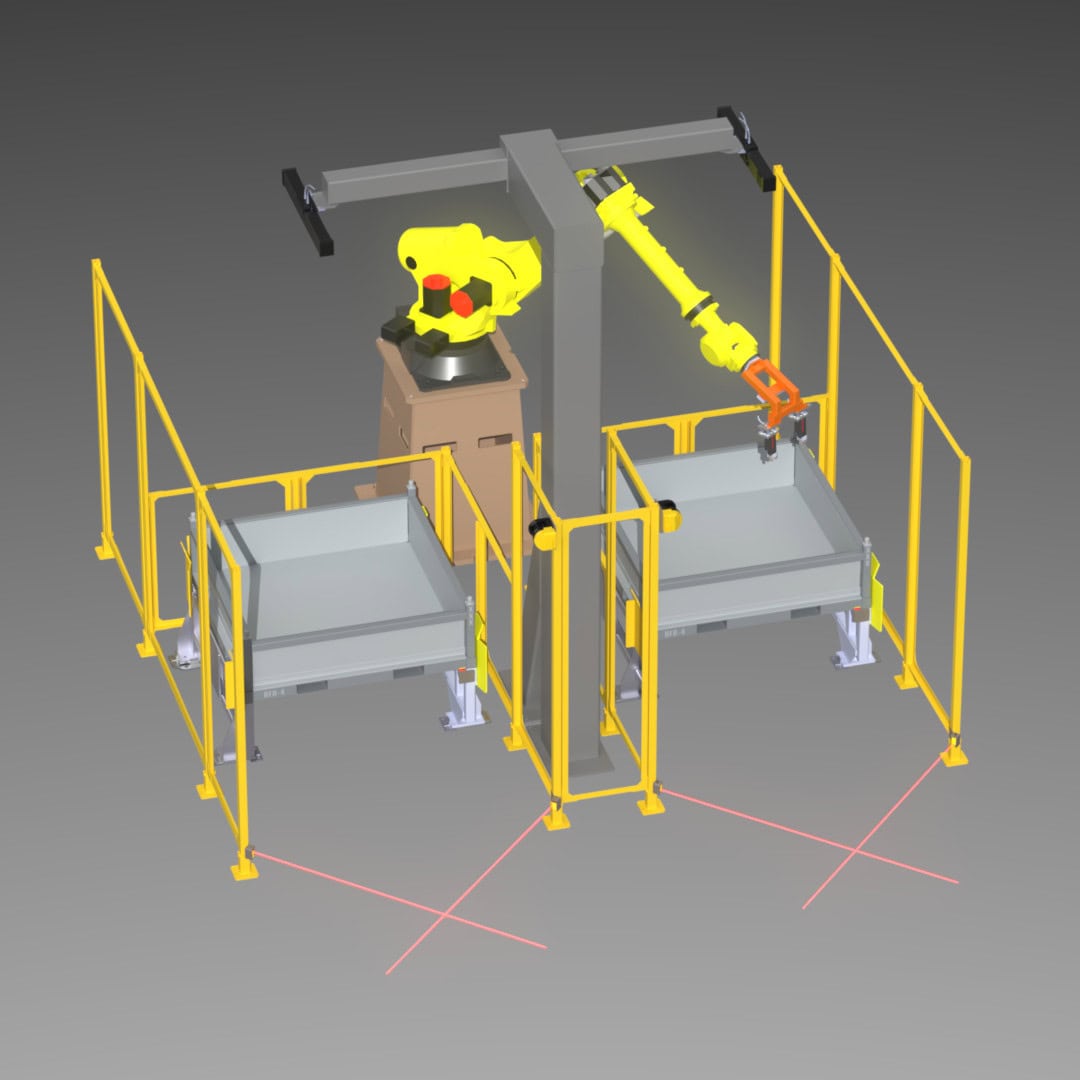

AMR Compact

Bins delivered by Autonomous Mobile Robots (AMRs) onto fixed stands.

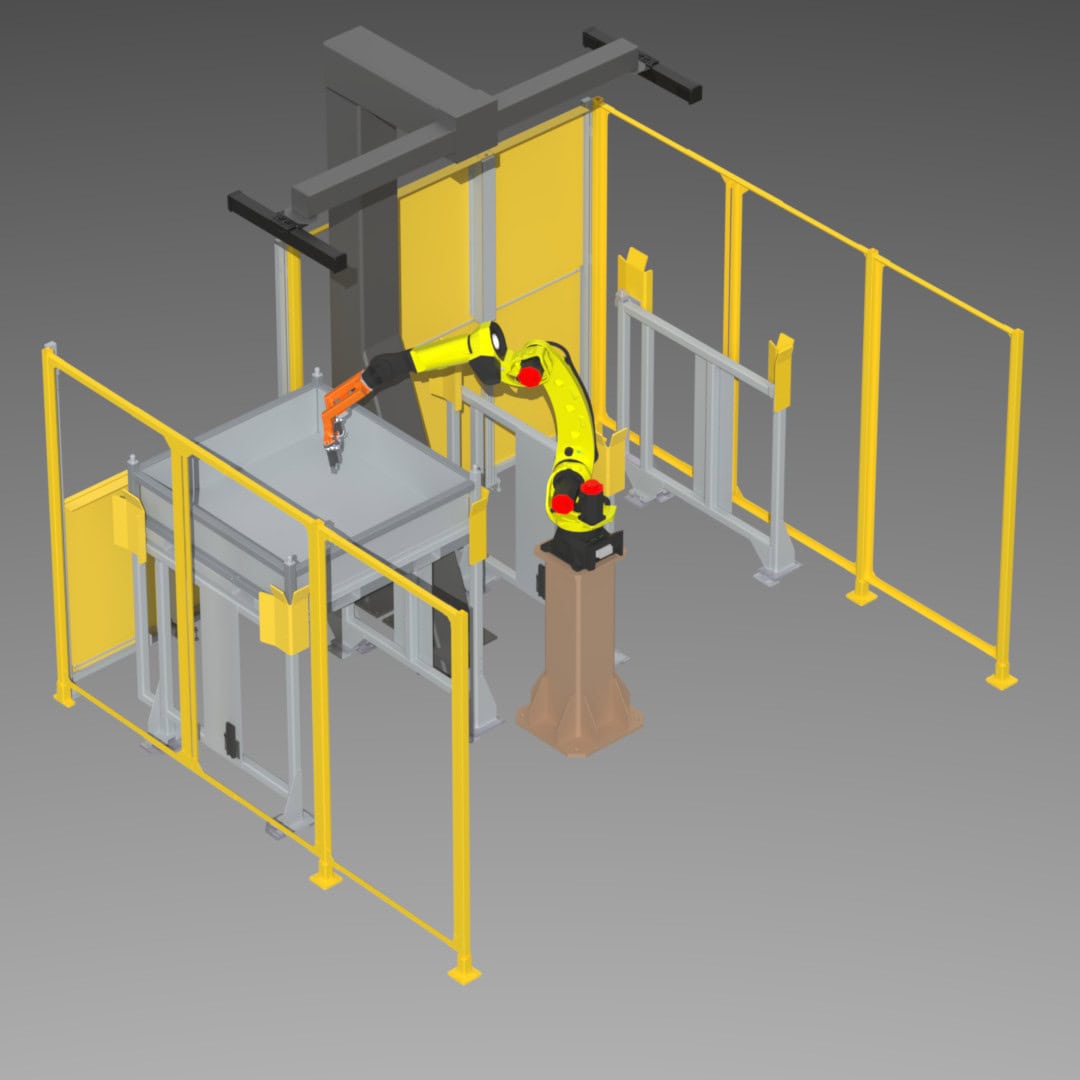

SD Compact

Forklift-loaded bins on fixed stands, sliding door (SD) access.

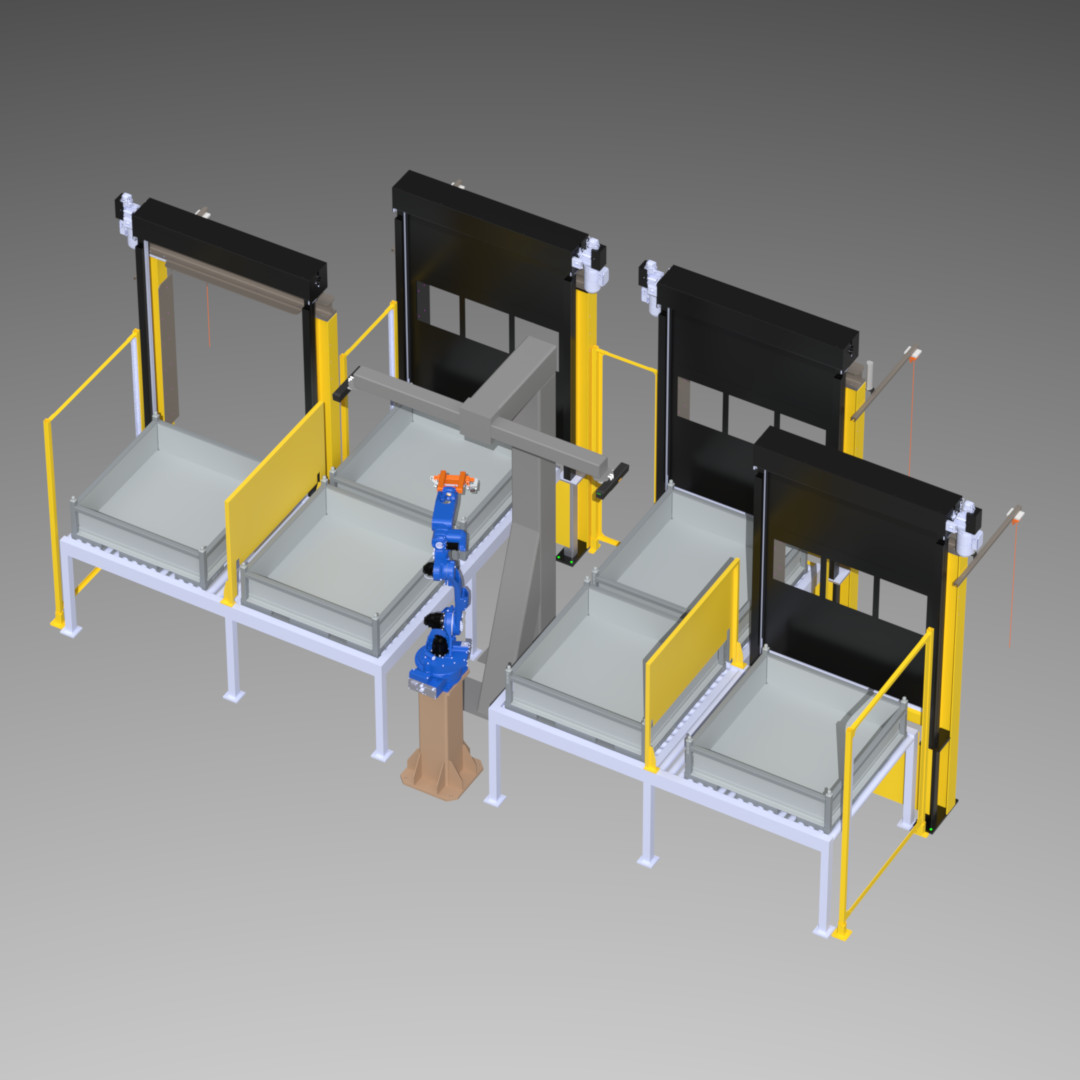

RUD Compact

Forklift-loaded bins on fixed stands; roll-up door (RUD) access.

RUD Conveyor

Forklift-loaded bins on roller conveyors; roll-up door access.

- Remote support from experts

-

Automation intelligence

- Part traceability

-

Full-scale automation integration expertise

-

Proven experience with material handling

-

Trusted turnkey partner

Empower your inspection solution with data analytics and inform your process and stakeholders with valuable short-and long-term insights.

Check out our preferred embedded solution: Proximity Smart Support™

TALK TO AN ENGINEER

Challenge us with your parts. We’ll validate the approach and help you plan deployment. Contact us today!