AI-POWERED 3D WELD SEAM INSPECTION

Inspect welds inline—catch defects before rework.

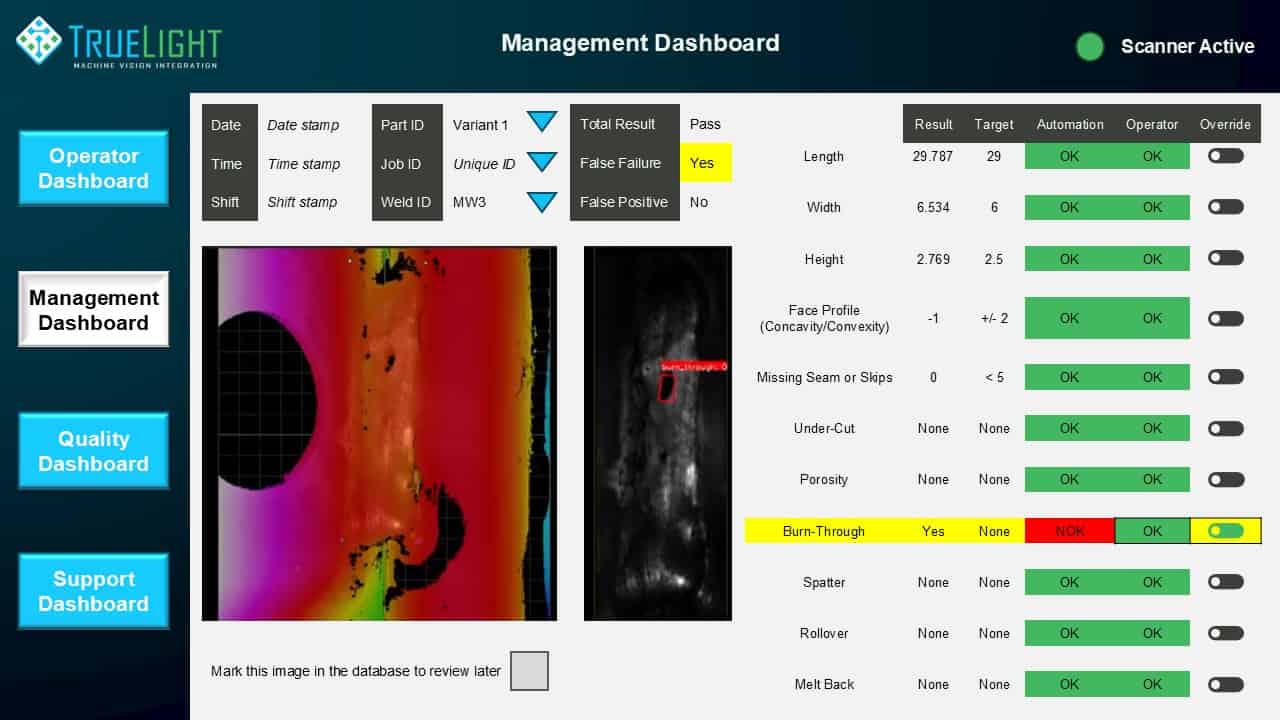

Increase the quality and profitability of your MIG welding process by automating weld seam inspections for faster problem identification and quicker resolution times. Our fully integrated solution allows you to inspect during manufacturing, not after, without slowing down production, minimizing rework, protecting your customer, and optimizing your use of skilled labour. Augment and optimize your quality control process with AI machine learning tools.

What Is 3D-AI Weld Inspection?

3D-AI Weld Inspection is an automated quality inspection method that uses 3D imaging and AI to evaluate welds for defects and dimensional inconsistencies. By capturing the weld’s surface profile and key geometric features, the system can detect issues then flag out-of-tolerance welds in real time. It’s designed for inline use, helping manufacturers standardize weld quality, reduce rework and scrap, and keep production moving.

Solution Features

Parallel image acquisition and processing to maximize speed of data transmission

Image segmentation to optimize inspection performance and speed of data transmission

Optimized performance using machine learning/AI and traditional toolsets in combination

Easily scaled for small and large applications

Automatic AI image labelling and storage of results for embedded analytics

Proximity Smart Support™ for real-time, expert support

Ethernet/IP communication is recommended, but alternative configurations such as Profinet are possible.

Easy to Use and Trust

Empower your trusted expert(s) with an easy to use interface to establish the ground-truth for the inspection solution.

Continuously improve performance by using the interface to mark the database for opportunities to reinforce or train the inspection solution.

- Remote support from experts

-

Automation intelligence

- Part traceability

- Full-scale automation integration expertise

-

Proven experience with welding systems

- Trusted turnkey partner

Empower your inspection solution with data analytics and inform your process and stakeholders with valuable short-and long-term insights.

Check out our preferred embedded solution: Proximity Smart Support™

TALK TO AN ENGINEER

Challenge us with your parts. We'll validate the approach and help you plan deployment. Contact us today!